Nicole Cuff

K-12 Education | Market Leader

Principal

As I am starting this blog I’m looking at my essentially silent lamp on my desk.

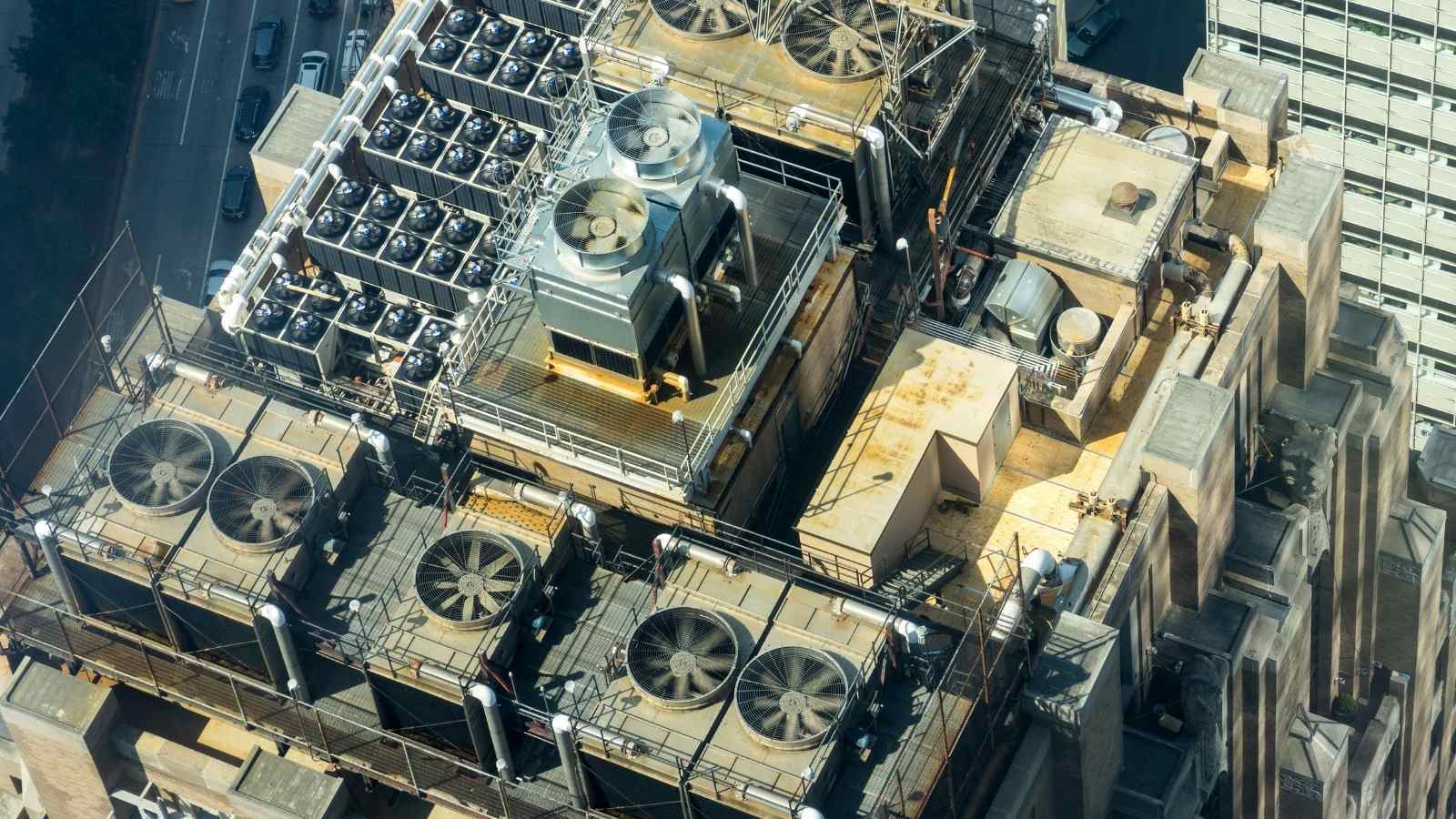

The main reason my lamp is so quiet is the actual source of electricity is far away from me, and there is no power generation happening at my lamp. There are plenty of noisy machines where the desired output is generated within the machine – like window air conditioning units, where the actual cooling is generated within the machine. And these are the noisiest kinds of machines – ones that generate their own electricity or their own cooling.

When I am asked to help a client with strategies to increase ventilation rates, all the more common now with COVID, I think about where to locate the new ventilation equipment based on the equipment’s noise level. I think about whether or not the machine is making its own cooling or electricity, or if it is relying on another machine far away for cooling or electricity.

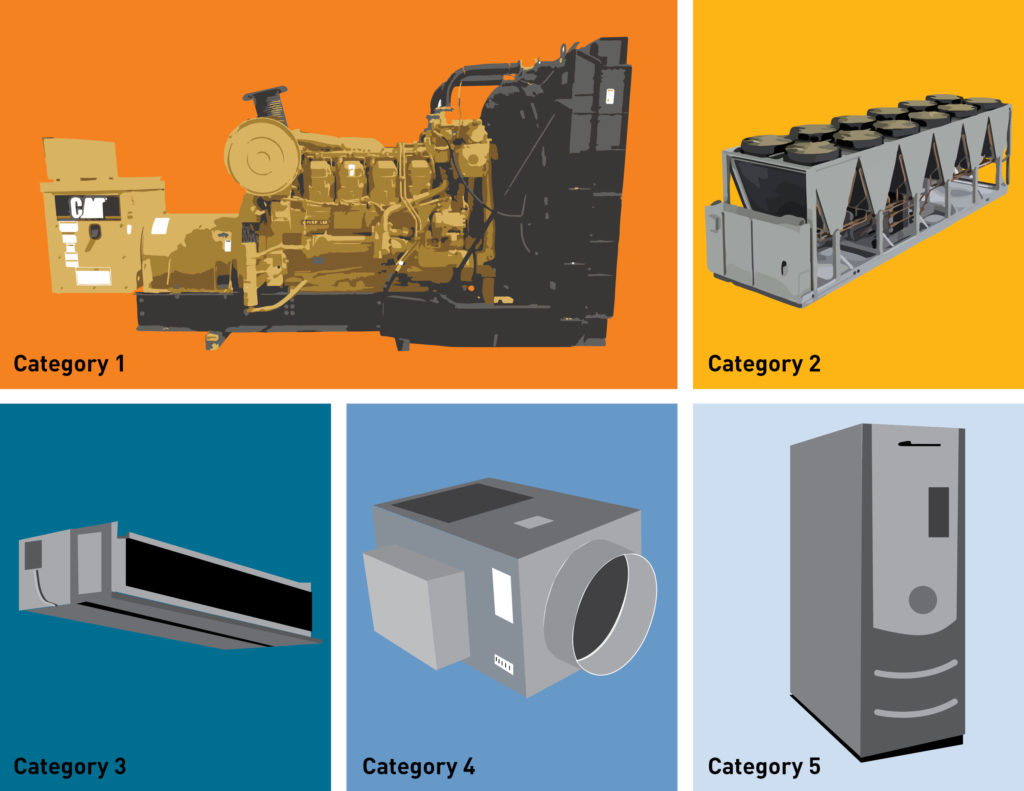

With this in mind, HVAC and electrical equipment can be categorized in one of five groups by their primary use (meaning some equipment will fall under multiple categories). In order from (approximately) the noisiest to least noisy, these equipment categories are:

1. Equipment that makes its own power – like generators, making their own power and not relying on the grid

2. Equipment that makes its own cooling – like window air conditioners or packaged rooftop units, including their own refrigerant components like compressors and condensers. This equipment can also be a cooling source for other equipment. This equipment may still need to rely on other equipment to complete the cooling system, but there is cooling within the machine.

3. Fan in a box – Blows air over coils to distribute cooling – the cold fluid is generated by another machine outside of this machine, likely from category 2

4. Damper in a box – Determines how much cold air is distributed into a room – the cold air is generated by another machine outside of this machine

5. Equipment that makes its own heating – Less equipment is needed for heating as compared to electricity or cooling

Equipment that falls under these categories includes:

1. Equipment that makes its own power

2. Equipment that makes its own cooling

3. Fan in a box

4. Damper in a box

5. Equipment that makes its own heating

Other equipment allows noise to transfer through it to the rest of the building, if connected by piping to other noisy sources. For the most part, this equipment is not a noise source itself. This category of equipment includes:

Ultimately, a successful approach for low-noise strategies while increasing ventilation rates for COVID-related design solutions relies on traditional noise control methods. These include locating new and noisy equipment far away from occupied spaces, larger sized ductwork to reduce velocity noise, sound attenuators to reduce fan discharge noise, and locating volume dampers far away from diffusers. Simply turning an existing fan to a higher speed to deliver more airflow means that the fan is both less efficient and noisier – so while that might be a short-term solution to increase air exchange rates, it is not a great long-term approach either for energy consumption or for noise. Most importantly, make sure that equipment that makes its own cooling or its own electricity is far from occupied spaces, so that the radiated noise from the equipment is far from potentially sensitive listeners.