Protective hood and face shields are often worn by surgical staff during orthopedic procedures to protect them from blood splashes and potentially infectious aerosols generated by power tools used by surgeons.

Such surgical helmet systems also decrease a patient’s risk of deep wound infection by keeping skin and other particles from the surgeon’s face from falling into the open surgical site. Due to the closed nature of the hood, there is need for ventilation, which is usually provided by a fan located on the hood. One manufacturer of these helmet systems came to Acentech seeking ways to improve the helmet sound after receiving feedback from surgeons that some helmets were noisy.

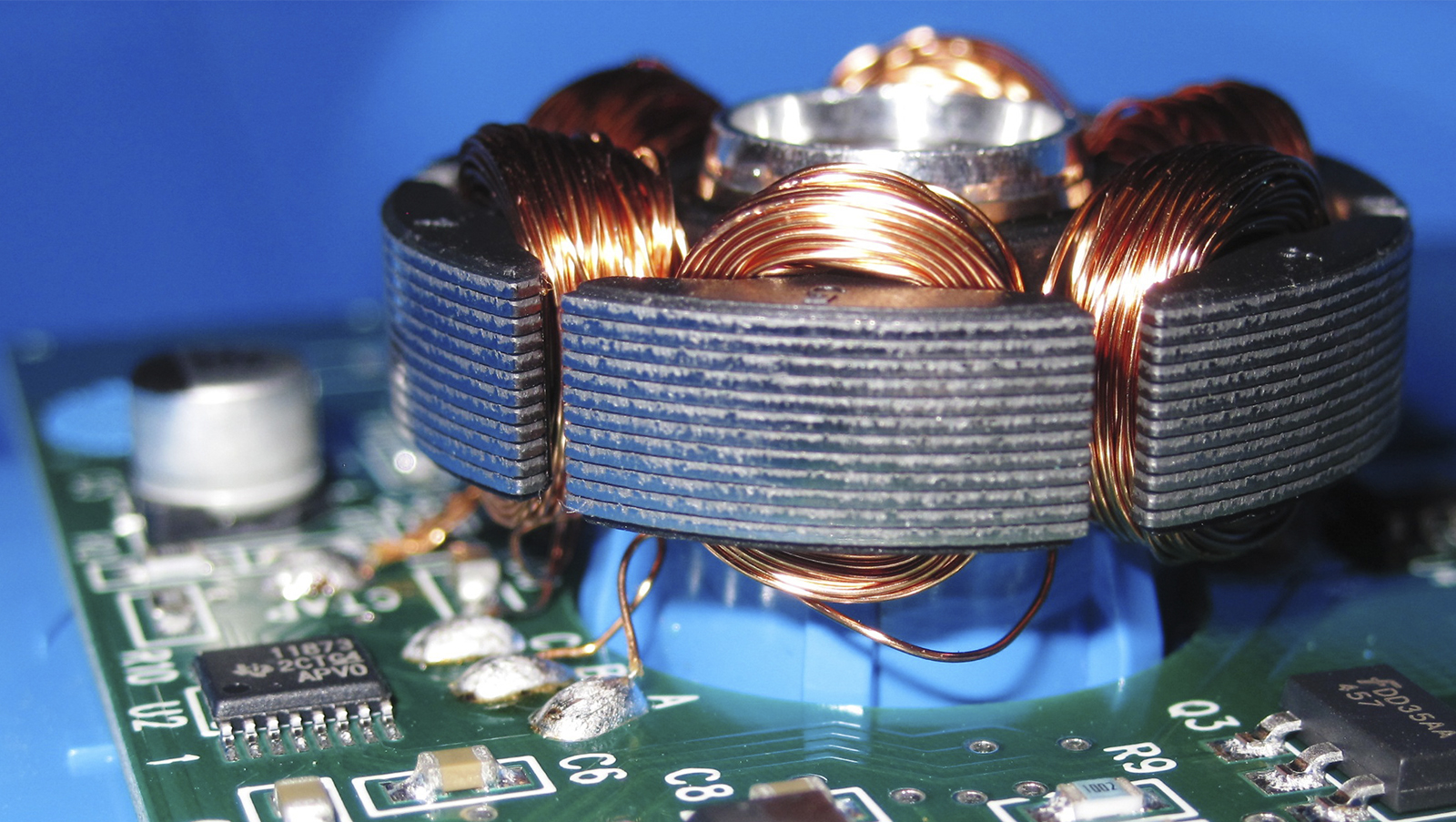

Acentech made use of an artificial head with microphones in the ear canals to characterize the helmet noise as experienced by wearers. This evaluation revealed that, in addition to the expected broadband flow noise, there were also strong tonal components present which could be particularly noticeable to users. Further analysis utilizing vibration measurements determined that these tones were structureborne in nature, originating from fan motor vibration at the motor’s elecromagnetic pole passage frequency and its harmonics. Since the fan motor was integral to the main circuit board and directly coupled to the helmet structure, parts of the helmet could efficiently radiate sound due to this vibration being transmitted from the motor. Subsequent analysis determined which region of the helmet was responsible for radiating most of this component of the noise.

Acentech’s main recommendation was to modify a small area of the helmet structure that was found to be the primary radiator of the tonal noise from the motor, so as to decrease the ability of the structure to radiate sound. Doing so reduced the amountof these tonal components by a noticeable 6 dB. In addition, we recommended a slight reduction in the length of a pair of outlet air vents so that their edges nearest the ears would be substantially further away, thus reducing the level of broadband noise reaching the ears.

The results and recommendations obtained from this project are being applied to the design of current and future helmet systems.