News

News

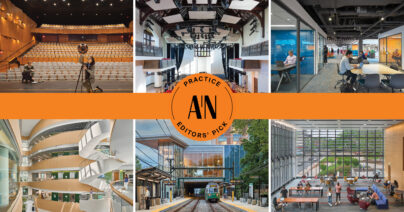

Acentech wins AN Best of Practice Award

Acentech is honored to be awarded an Editors’ Pick in The Architect’s Newspaper 2025 Best of Practice Awards in the Acoustic Consultant/Engineer category! This recognition highlights…

One of the fundamental products that design and development professionals offer is shelter, in its many forms. We want the buildings we design to be safe, efficient, healthy, and comfortable. Home should be a place that offers a respite from the anxieties of modernity, especially the constant barrage of noise and vibration that we are exposed to daily in the urban environment.

In cities, shelter increasingly takes the form of tall multi-story buildings. Where 30 years ago buildings in excess of 5 floors were relatively rare in Boston, the recent construction boom in our city has led to the development of a large number of luxury condominium buildings in excess of 20 floors. Providing efficient and equitable vertical transport is the job of an elevator, and this blog will focus on the sound and vibration that these machines produce.

In Boston, where we have a lot of relatively old buildings, there are several elevator technologies that we encounter in our work. These include hydraulic, machine-room-less (MRL), and traction elevators. Generally, hydraulic and MRL elevators are limited to low- and mid-rise buildings (less than 8 stories), and move at speeds of less than 500 ft/min.

Elevator design has evolved significantly in the last few decades, largely in response to the demands presented by ever taller buildings. To provide quick service to the top of a modern 20-story building, the only real player in the elevator game is the gearless traction elevator.

People form rapid judgments about quality based on the sounds and vibrations that a product makes. Consider the case of a high-end automobile, where the slam of the door almost seems to say “you are safe here friend”. Were the door to sound “hollow” or to exhibit a “rattle”, wouldn’t you be a little anxious taking this machine down the highway at speed?

With a car there are additional things we can do to stay safe, such as driving slower and exercising defensive driving; we can also kick the tires and open the hood. But what about when we cannot inspect the product under question, have no innate knowledge of its design and construction, and must form judgments about our own safety in seconds given a dizzying array of variables?

In the absence of complete information, people often rely on the information that is available. Because we can typically feel vibration in our feet and hear sound when we are riding an elevator, these acoustic cues are significant indicators of the quality of the elevator, and hence our safety. It also follows that a building with a “cheap” sounding elevator also implies that other aspects of the building are cheap, lessening the perceived value of the building on the market.

Fortunately, standards exist to quantify the sound and vibration experienced by an elevator rider and to compare it to generally-accepted criteria. In this regard, the methods described in the ISO Elevator Ride Quality standard are invaluable, both during elevator commissioning, and to respond to concerns once the building is occupied. It has been our experience that complaints related to sound and vibration are much less likely to emerge when the elevator achieves the ISO criteria for ride quality. This standard provides recommended motion criteria for lifts in quantities of velocity (m/s), acceleration (m/s2), and even the rate of change in acceleration called jerk (m/s3). A “jerky” elevator may cause riders to lose balance.”

So, what can be done if you are concerned that the elevator in your building may not be functioning correctly?

In that elevators are machines of very high precision, it is often necessary to involve a millwright, machinist, or similar skilled trade to make the final adjustments that the design and ownership team agrees to. Once the adjustments have been made, a second round of acoustic measurements is useful to quantify the effectiveness of the work and to determine if additional adjustments should be made.