Eric E. Ungar

Chief Engineering Scientist Emeritus

The vibrations in a research facility can place severe limits on the measurements and investigations that can be done there. “Zero vibration” is not possible, but particularly sensitive facilities strive toward the lowest achievable vibration environments. For especially sensitive research, organizations like the National Institute of Standards and Technology, Cornell University, and Princeton University, among others, have built special “quiet” laboratories in their facilities.

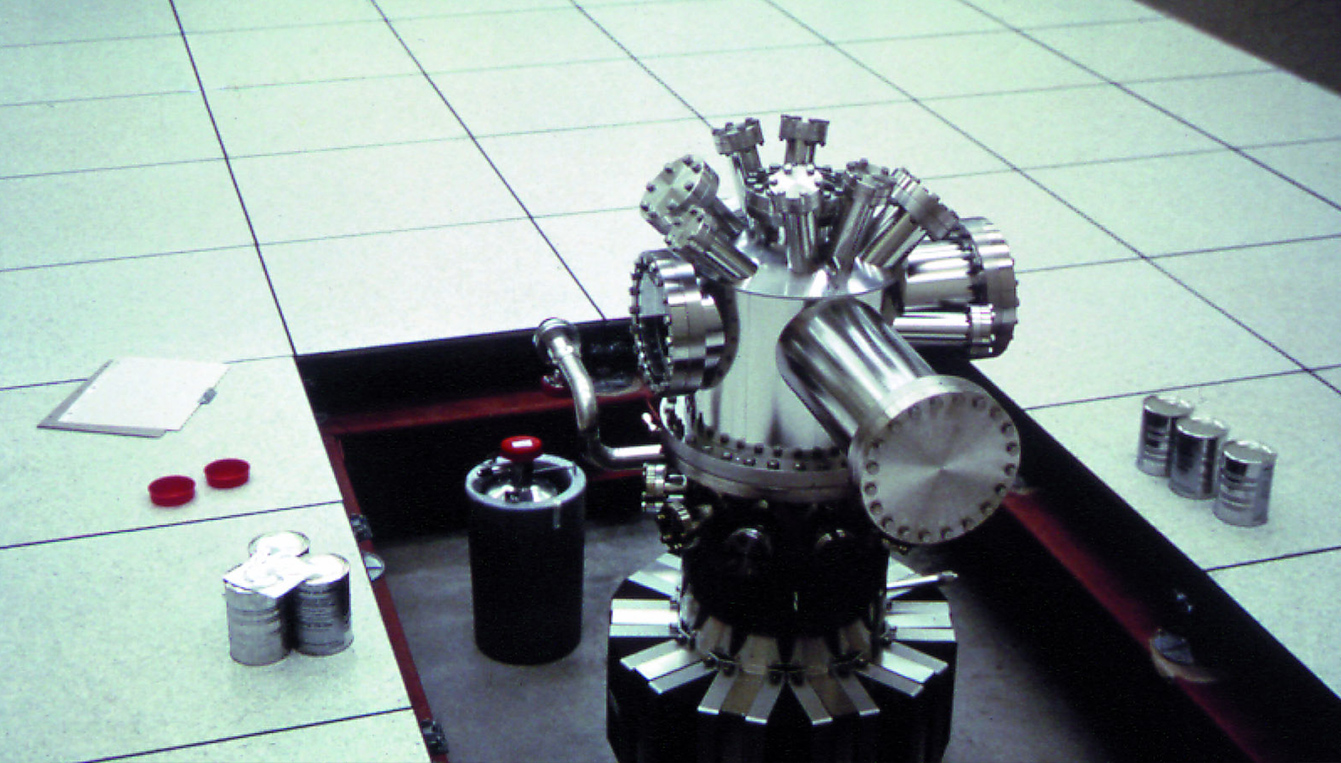

Quiet labs invariably are located in quiet areas of quiet structures and employ vibration isolation to reduce further the vibrations transmitted to the sensitive equipment. The isolation systems typically employ a large rigid block (usually of concrete) supported on very soft springs (usually air-springs); the sensitive item is located on the isolated block. If even more isolation is needed, the inertia-block/air-spring isolation can be augmented by an “active” system. Such systems employ sensors, a controller and actuators to counteract vibrations.

It has become common practice to characterize vibration environments in terms of the root-mean-square (rms) velocities measured in one-third-octave-bands of frequency and to assign “Vibration Criterion” (VC) letter designations to various magnitudes. VC-A represents the rms velocity magnitude of 2,000 micro-inches per second (µ-in/s). This is a typical design goal for general laboratory spaces. Since the threshold of perception of the most sensitive humans is at about 4,000 min/s, people cannot feel vibrations at a level of VC-A. The VC levels decrease by a factor of 2 for each progressive letter of the alphabet. Thus, VC-B corresponds to 1,000 µ-in/s and VC-C to 500 µ-in/s, etc. For very sensitive usages such as precision imaging and nano-technology, design goals ranging from VC-E (120 µ-in/s) to VC-G (30 µ-in/s) are commonplace.

It is very difficult to achieve a vibration environment much lower than VC-G. One needs to select a quiet location (typically, in the basement or on an on-grade slab) in a building that is situated in an area where the vibrations in the ground are relatively benign. Although the vibrations in the basement of a completed building may be smaller than the vibrations in the soil before the building was built, the ambient vibrations in the ground place a limit on the quiet that can be achieved. Also, a building’s mechanical systems and some of the research-related equipment tend to inject vibration into the building; these items can certainly be isolated, but there is a limit on what can be done practically.

This is why isolation systems as described above are used. Such systems can be used, for example, on a VC-E slab-on-grade floor to provide isolated “islands” with levels well below VC-G. In fact, on a recent project of ours, air-spring supported concrete blocks were used to provide a floor vibration environments well below VC-G – in fact, so low that they could not be measured with even the best commercially available instrumentation.