Jeffrey A. Zapfe

Higher Education | Market Principal

Principal

Buildings near rail lines are subjected to vibration that can be disruptive to occupants. As vibrations travel up through a building’s columns they decrease floor-by-floor as each extracts a little bit of the vibration energy. Our research explores the potential benefits of an intentionally thick floor to significantly reduce the vibrations transmitted to the floors above it.

Buildings situated in dense urban settings are subjected to environmental vibrations from a wide array of sources that include rail and subway lines, roadways and industrial facilities. In extreme cases ground-borne vibrations can adversely affect the building occupants as feelable vibration, re-radiated noise or both.

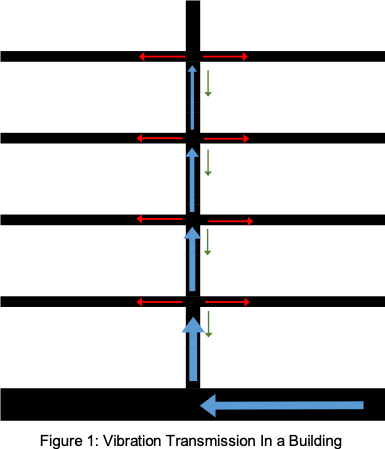

Environmental ground-borne vibration generally enters a building at the foundation. Once inside, the vibrations travel upward primarily through the structural members, usually the building columns. As the vibrations travel upwards, floor slabs act as discontinuities that reflect energy back toward the foundation and also remove energy due to transmission out into the floor. Figure 1 shows the conceptual vibration energy flow through one column in a building. Every floor removes a little bit of energy which means the vibrations levels decrease as they travel upward. According to the Federal Transit Administration (FTA)1 the vibration amplitudes decrease by about 20% per floor, a relationship that has been reliably observed in many buildings near rail lines.

Fortunately, the FTA provides methods to estimate the vibrations in a building near a rail line – before it is built. A significant issue arises when the predicted vibrations exceed the building’s design goals based on its occupancy. In cases where the vibrations are expected to be too high, building base isolation systems are a common method employed to mitigate the vibration impacts. Base isolation involves the placement of resilient pads within the structural system. This decouples the foundation from the columns thereby minimizing vibration transfer to upper floors. In the most common application, resilient elements are placed between the column bases and the foundation. The classic implementation of building base isolation is a concert hall next to a rail line, Benaroya Hall in Seattle being a relatively recent example.

Effective base isolation systems can be very expensive with the cost typically increasing as the isolation springs get softer. Added to the basic material costs are the increased design complexity to avoid vibration short circuits while maintaining the necessary horizontal restraints to resist wind and seismic loads.

Our research began with the questions, “If floors can remove vibration energy, could an overly thick floor remove enough energy to make a significant difference?” Perhaps enough of a difference to make a base isolation system unnecessary?

The potential cost savings of this could be significant as the overly thick floor would replace a very expensive and complex isolation system with essentially more steel and concrete.

As a first step we considered each floor to be an infinite plate that removed energy from the column. The particular attractiveness of this was the existence of a very simple expression for the mechanical impedance of an infinite plate:

![]()

where ![]() is the material density of the plate material and

is the material density of the plate material and ![]() is the plate thickness.

is the plate thickness. ![]() is the bending rigidity of the plate where

is the bending rigidity of the plate where ![]() with

with ![]() and

and ![]() being the Young’s modulus and Poisson ratio of the material, respectively.

being the Young’s modulus and Poisson ratio of the material, respectively.

While Equation 1 is certainly simple and easy to use, it has two important drawbacks. First, since it represents a point impedance it does not represent the conditions at a real column which has finite dimensions. Secondly, a point force, theoretically creates an infinite shear force at the point of application which introduces a mathematical singularity and associated computation problems.

In order to account for a finite column we developed an impedance expression for an infinite plate with a finite, massless rigid plug. This allowed us to model finite-sized columns with appropriate boundary conditions at the floor-column interface.

Equation 1 is the impedance expression for a Kirchoff plate which is the plate equivalent of an Euler beam. In both these models, the assumption is that planes that were normal to the neutral axis before bending remain normal to the neutral axis after deformation. In essence this means there is no shear deformation in the beam or plate, which is certainly not true for thick plates and beams. There are many advanced models for plates and beams that account for shear deformation. The most common model for plates is the Mindlin model which includes shear deformation.

We developed impedance expressions for both Kirchoff and Mindlin plates. The mathematical development is quite involved and we will not present it here, but if you are interested it can be found in our research paper that appeared in the Journal of the Acoustical Society of America2.

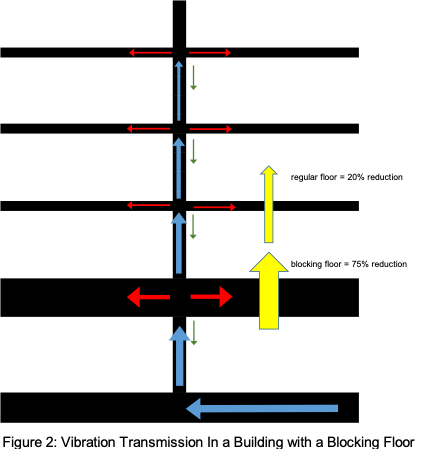

Using representative columns (W14x109) and floors (5″ NWC) that might be found in a lab-type building, our models predicted floor-to-floor attenuation rates that were quite similar to the FTA predictions – about 20% for the 5″ floor. But, even more interesting was the fact that our model predicted that the vibrations reduction would be about 75% with a 4x thicker floor (20″). A reduction of this magnitude is actually comparable to what could be expected with a base isolation system.

Figure 2 shows how a blocking floor might be used conceptually in a building. This figure shows the floor as the first above grade floor which seems to make sense from a structural standpoint, but is could theoretically be located anywhere. It is important to note that the blocking floor need not have the same usage as others in the building, it could easily be a parking or amenity level.

Unfortunately we have not had the opportunity to illustrate the effectiveness of a blocking floor in a real building. If you have an interest in this concept and have a project where it might be applicable, or you would simply be interested in exploring a blocking floor’s potential from a research perspective, we would love to talk to you. And interestingly, a proof-of-concept implementation need not be done on a normally-occupied building – a parking garage near a rail line could just as effectively serve as a full scale test bed.

1“Transit Noise and Vibration Impact Assessment Manual”, Federal Transit Administration, FTA Report No. 0123, September 2018.

2“Impedance of infinite Kirchhoff and Mindlin plates with a rigid circular massless plug,” Jeffrey A. Zapfe and James A. Moore, JASA, v. 131 (5), May 2012.